Solutions

Solutions

Case05

Cracking

The steel is composed of “crackable” materials.

The steel may appear sturdy and stable, but can easily crack if the heating conditions and control methods are incorrect.

Many cracks are too small to be seen by the naked eye. Undetected cracking can lead to damage and, in the worst case, serious accidents.

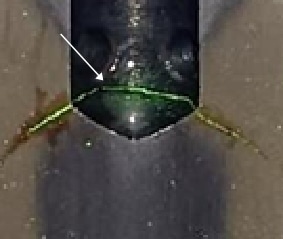

Cracks have developed in the spline area of the shaft.

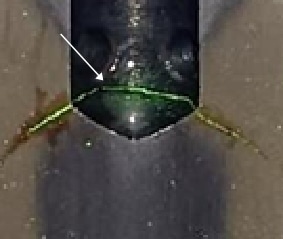

The outer diameter is reduced by a notch and there is a hole in the center, making the wall of the cracked area thin.

Looking at the cross-section, the thin area is through hardened, which, along with the spline machining on the surface, caused concentrated stress leading to cracking.

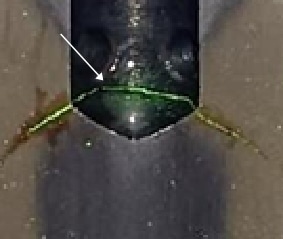

Fuji Electronics’ one-shot hardening can achieve a uniform hardening layer through whole heating and cooling with profile-fitting coils.

The heating time is significantly reduced and, as a result, the cycle time is less than half that of traditional scan hardening, contributing to increased productivity.

Many cracks are too small to be seen by the naked eye. Undetected cracking can lead to damage and, in the worst case, serious accidents.

Cracks have developed in the spline area of the shaft.

The outer diameter is reduced by a notch and there is a hole in the center, making the wall of the cracked area thin.

Image ① Spline Cracking

Looking at the cross-section, the thin area is through hardened, which, along with the spline machining on the surface, caused concentrated stress leading to cracking.

Image ② Spline Cross-Section

Fuji Electronics’ one-shot hardening can achieve a uniform hardening layer through whole heating and cooling with profile-fitting coils.

Image ③ Hardening Pattern of One-Shot Hardening

The heating time is significantly reduced and, as a result, the cycle time is less than half that of traditional scan hardening, contributing to increased productivity.

Image ① Spline Cracking

Image ② Spline Cross-Section

Image ③ Hardening Pattern of One-Shot Hardening

▲