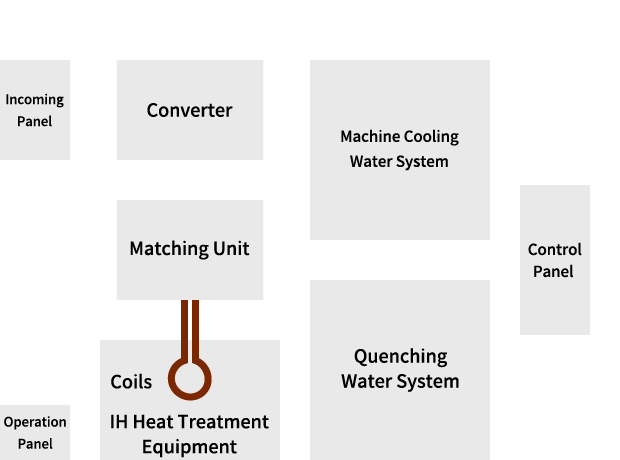

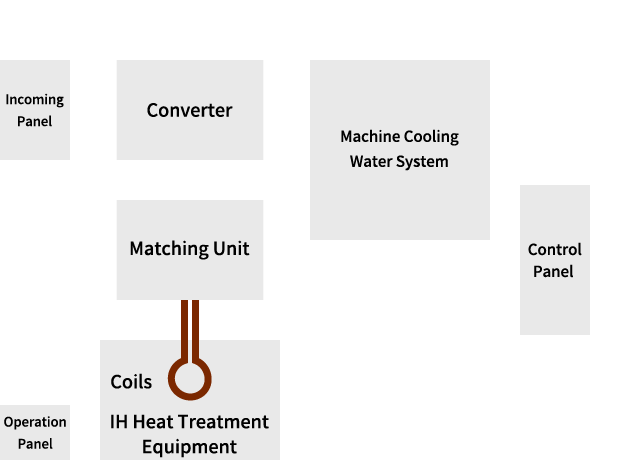

Equipment Configuration

Equipment Configuration

Converter

Converts the power supplied from the incoming panel to the high-frequency power required for heat treatment processing.

Machine Cooling Water System

Supplies pure water to cool the heat-generating parts in the converter, matching unit, and coils. The cooling water is temperature controlled.

Quenching Water System

This unit supplies quenching water to cool the workpiece after heating. The quenchant is temperature-controlled.

Control and Operation Panel

The operation panel controls all system processes, displays actual values of heating conditions, and performs setting changes.

Incoming Panel

Adjusts the primary voltage supplied by the customer to the voltage required for the converter.

IH Heat Treatment Equipment

We design and manufacture equipment configurations to suit your pre- and post-processes and cycle times, from manually-loaded to fully automated.

Matching Unit

Converts the high voltage/low current output from the converter to the low voltage/high current required for heating and supplies it to the coil.

Coils

We design and manufacture coils to effectively and efficiently supply power to the workpiece, in accordance with the heating specifications.

Converter

Converts the power supplied from the incoming panel to the high-frequency power required for heat treatment processing.

Machine Cooling Water System

Supplies pure water to cool the heat-generating parts in the converter, matching unit, and coils. The cooling water is temperature controlled.

Control and Operation Panel

The operation panel controls all system processes, displays actual values of heating conditions, and performs setting changes.

Incoming Panel

Adjusts the primary voltage supplied by the customer to the voltage required for the converter.

IH Heat Treatment Equipment

We design and manufacture equipment configurations to suit your pre- and post-processes and cycle times, from manually-loaded to fully automated.

Matching Unit

Converts the high voltage/low current output from the converter to the low voltage/high current required for heating and supplies it to the coil.

Coils

We design and manufacture coils to effectively and efficiently supply power to the workpiece, in accordance with the heating specifications.

Converter

Converts the power supplied from the incoming panel to the high-frequency power required for heat treatment processing.

Machine Cooling Water System

Supplies pure water to cool the heat-generating parts in the converter, matching unit, and coils. The cooling water is temperature controlled.

Quenching Water System

This unit supplies quenching water to cool the workpiece after heating. The quenchant is temperature-controlled.

Control and Operation Panel

The operation panel controls all system processes, displays actual values of heating conditions, and performs setting changes.

Incoming Panel

Adjusts the primary voltage supplied by the customer to the voltage required for the converter.

IH Heat Treatment Equipment

We design and manufacture equipment configurations to suit your pre- and post-processes and cycle times, from manually-loaded to fully automated.

Matching Unit

Converts the high voltage/low current output from the converter to the low voltage/high current required for heating and supplies it to the coil.

Coils

We design and manufacture coils to effectively and efficiently supply power to the workpiece, in accordance with the heating specifications.

Converter

Converts the power supplied from the incoming panel to the high-frequency power required for heat treatment processing.

Machine Cooling Water System

Supplies pure water to cool the heat-generating parts in the converter, matching unit, and coils. The cooling water is temperature controlled.

Control and Operation Panel

The operation panel controls all system processes, displays actual values of heating conditions, and performs setting changes.

Incoming Panel

Adjusts the primary voltage supplied by the customer to the voltage required for the converter.

IH Heat Treatment Equipment

We design and manufacture equipment configurations to suit your pre- and post-processes and cycle times, from manually-loaded to fully automated.

Matching Unit

Converts the high voltage/low current output from the converter to the low voltage/high current required for heating and supplies it to the coil.

Coils

We design and manufacture coils to effectively and efficiently supply power to the workpiece, in accordance with the heating specifications.