Solutions

Solutions

Case02

Increasing Production and Quality

Semi-Open Coil One-Shot Hardening

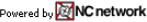

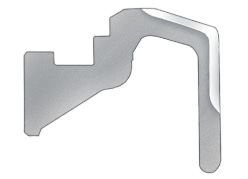

The part in Fig 1. is part of the suspension of an agricultural machine and requires hardening due to exposure to roads and gravel.

Traditional scan hardening methods required a cycle time of 360 seconds, resulting in only 10 parts hardened per hour.

Fig.1 Macropattern

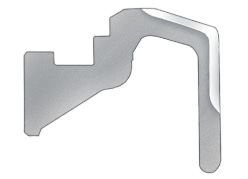

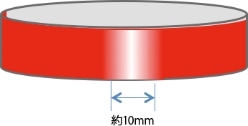

Scan hardening also produces soft zones at the start and end of the target area.

These soft zones are left unhardened to avoid possible cracking during re-hardening.

Compared to the hardened areas (min. HV600), the soft zones (approx. HV250) are vulnerable to erosion and result in shorter part life.

Fig.2 Soft Zone

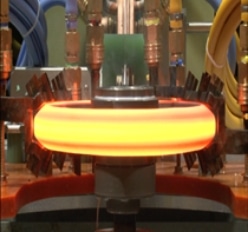

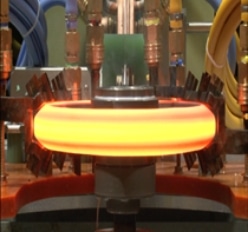

Fuji Denshi’s one-shot dip-spray quenching method creates an even casing in 1/4 the cycle time (90 sec/part) of scan hardening.

The increase in quality and production is thanks to our semi-open coil.

By only covering half of the circumference of the part, loading and unloading require less time.

The coil and part maintain a constant gap with no chance of damage from collision.

Handling is done by robot and heating control prevents overheating.

Fig.3 Semi-Open Coil Heating

Fig.1 Macropattern

Fig.2 Soft Zone

Fig.3 Semi-Open Coil Heating

▲